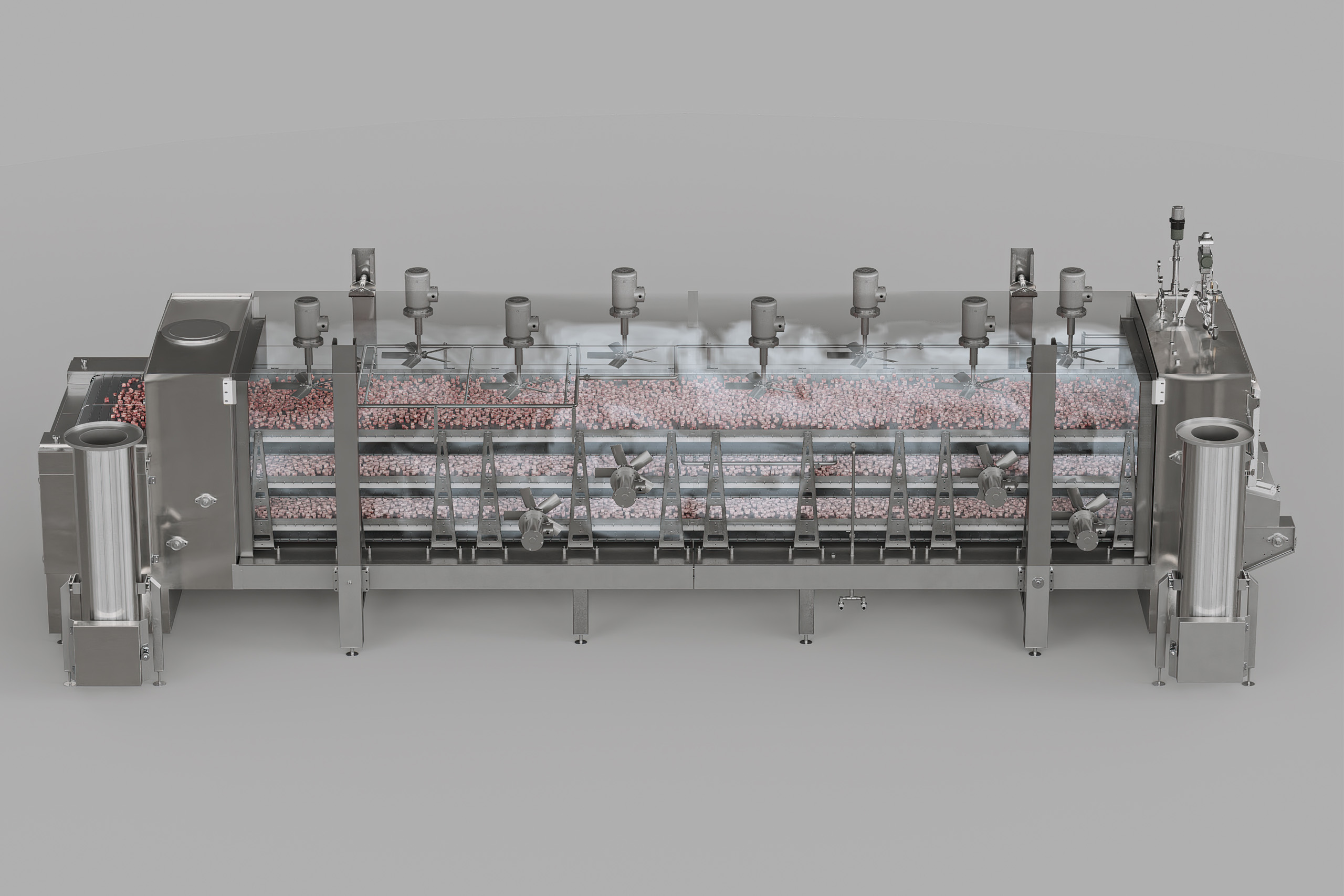

IQF batch freezers

Cryogenic batch equipment is ideal for food and metal treatment.

In the case of food, it is especially relevant for freezing and chilling food that require no linear or continuous procession along a line, e.g. in small companies or product lines, testing applications or institutions with inhouse cafeterias. In terms of metal treatment, cryogenic batch freezing is often used for sub-zero treatment in the auto, aviation, aerospace, and machine tooling industries.

Our cryogenic batch freezers and batch chillers are based on the same freezing process, where liquid is sprayed, and vapor is circulated by fans to ensure rapid freezing and chilling. Controlled over-pressure inside the equipment pushes the excessed gas out – this is also known as 'passive exhaust'. This makes the solution easy to install, as it doesn’t need an external exhaust blower or a gas purge.

The batch chiller and freezer have adjustable nozzles to handle changing requirements or items requiring slower freezing or chill time to prevent surface fractures.

Our range of batch freezers and batch chillers cover a freezer that comes in a single and double batch version and a cryogenic treatment chamber.