Superior freezing or chilling

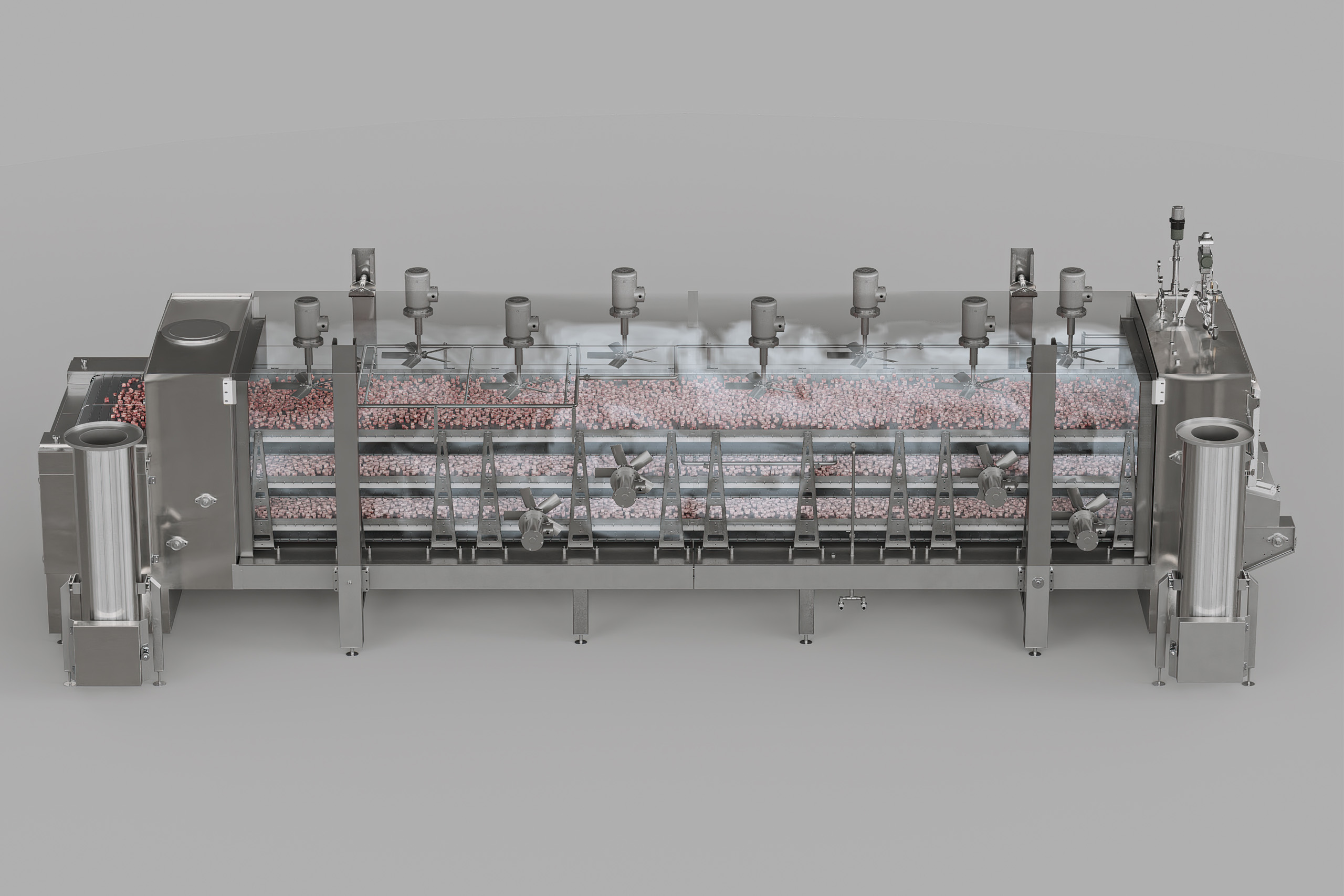

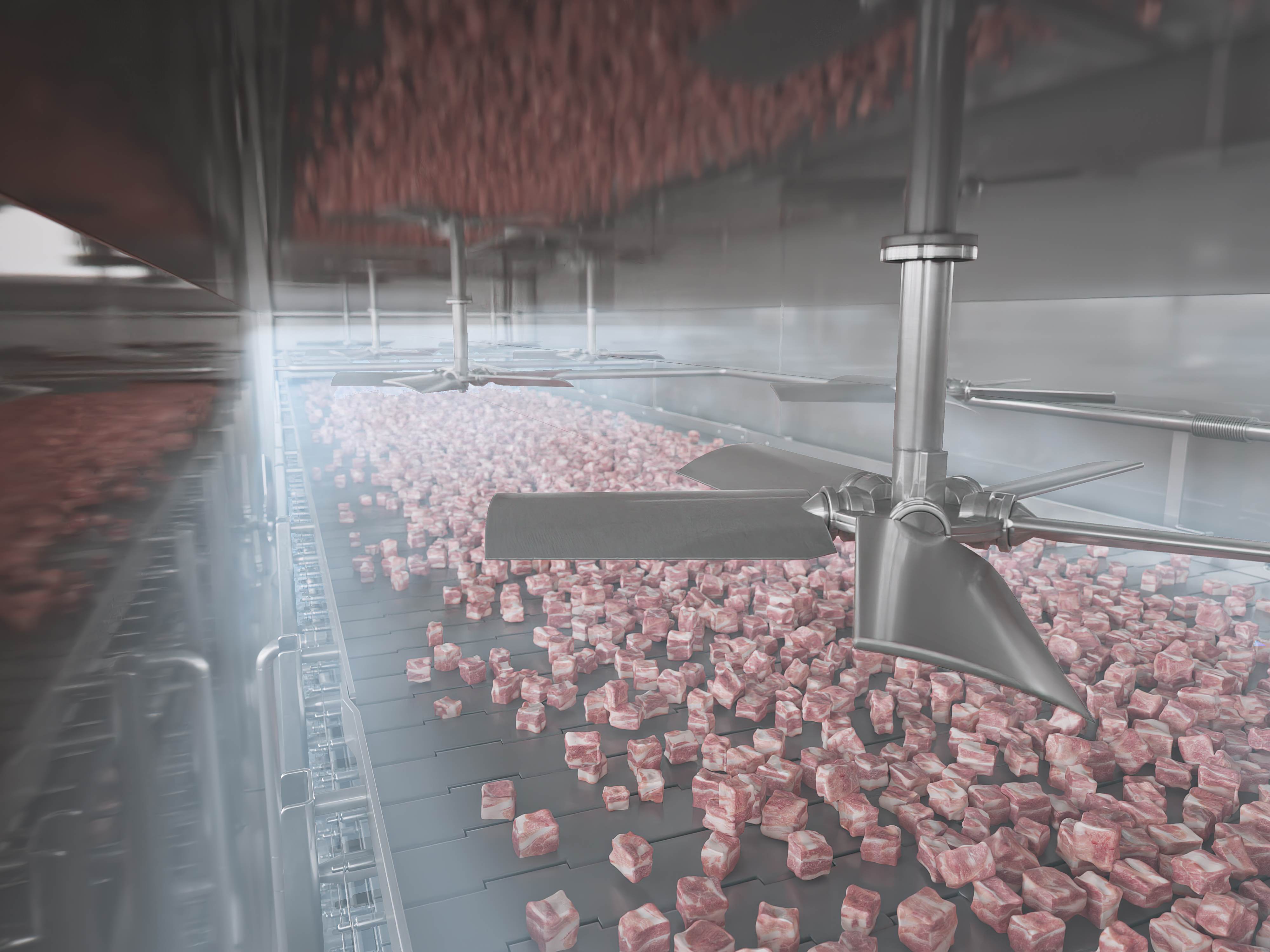

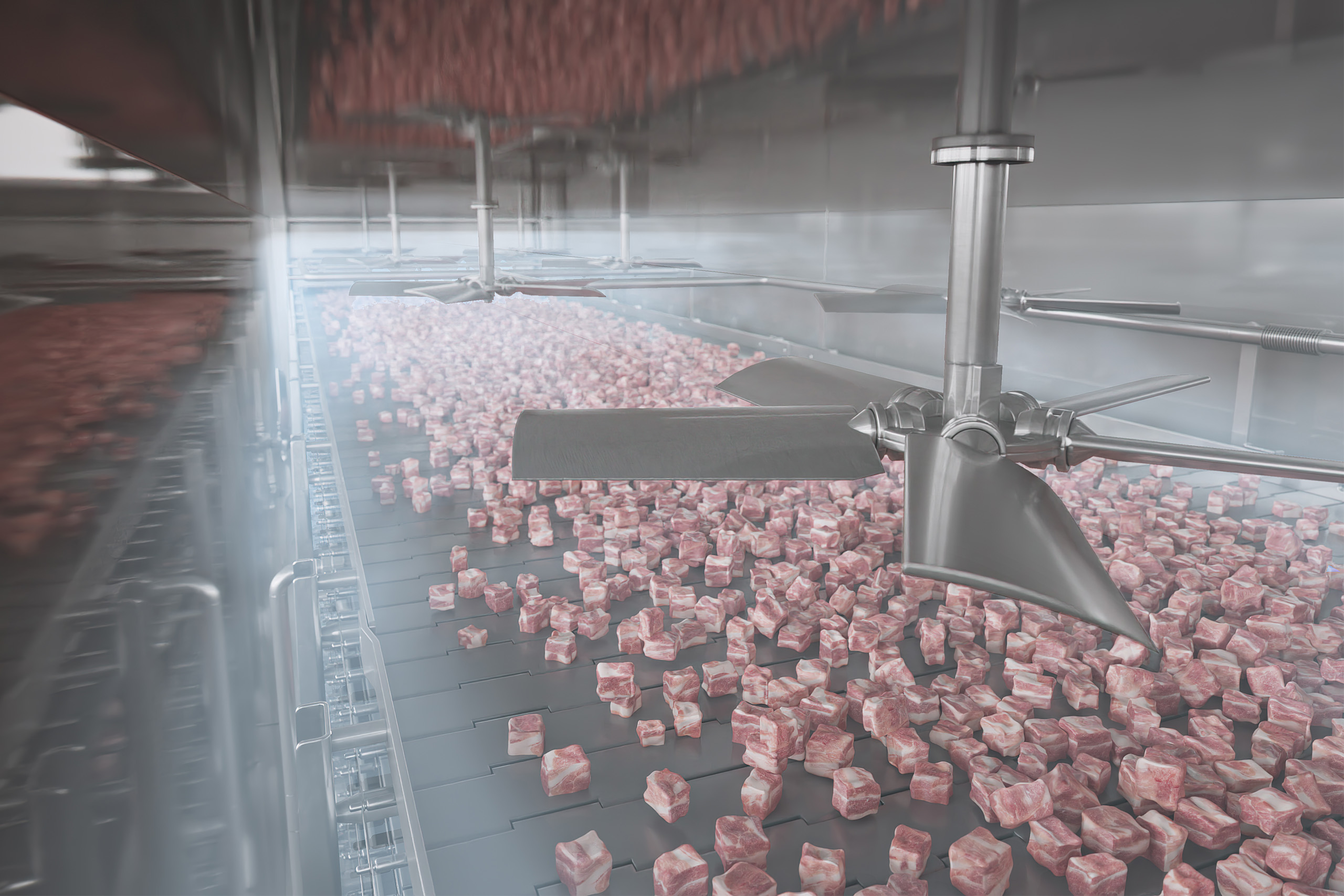

Our tunnel freezers are ideal for cooling, chilling, and freezing a wide variety of food. With our tunnel freezer variants, you can process everything from small items such as burger patties and diced meats, berries, or vegetables that tend to freeze together to high-volume products and foods with prolonged cycles such as meats, seafood, and baked goods.

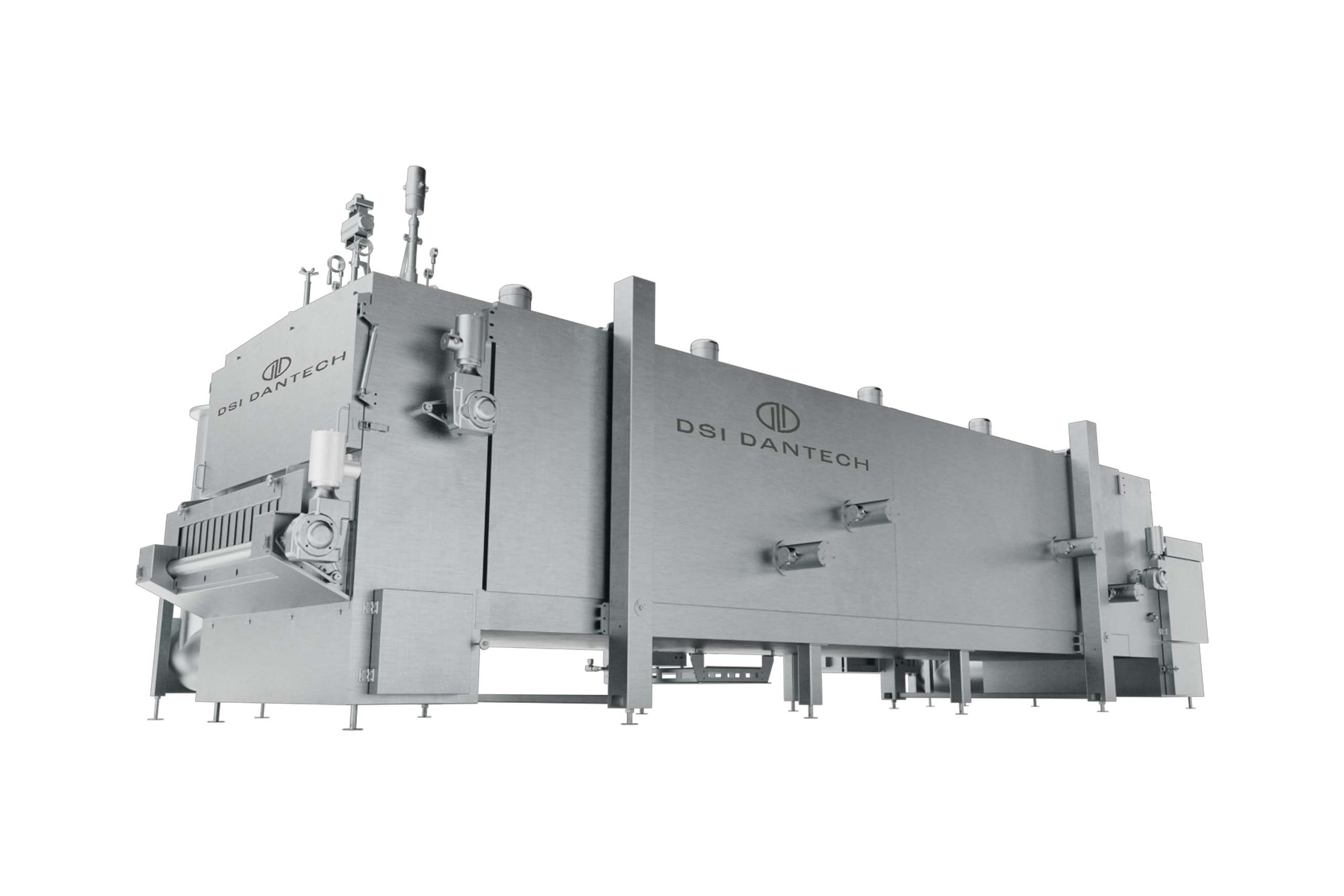

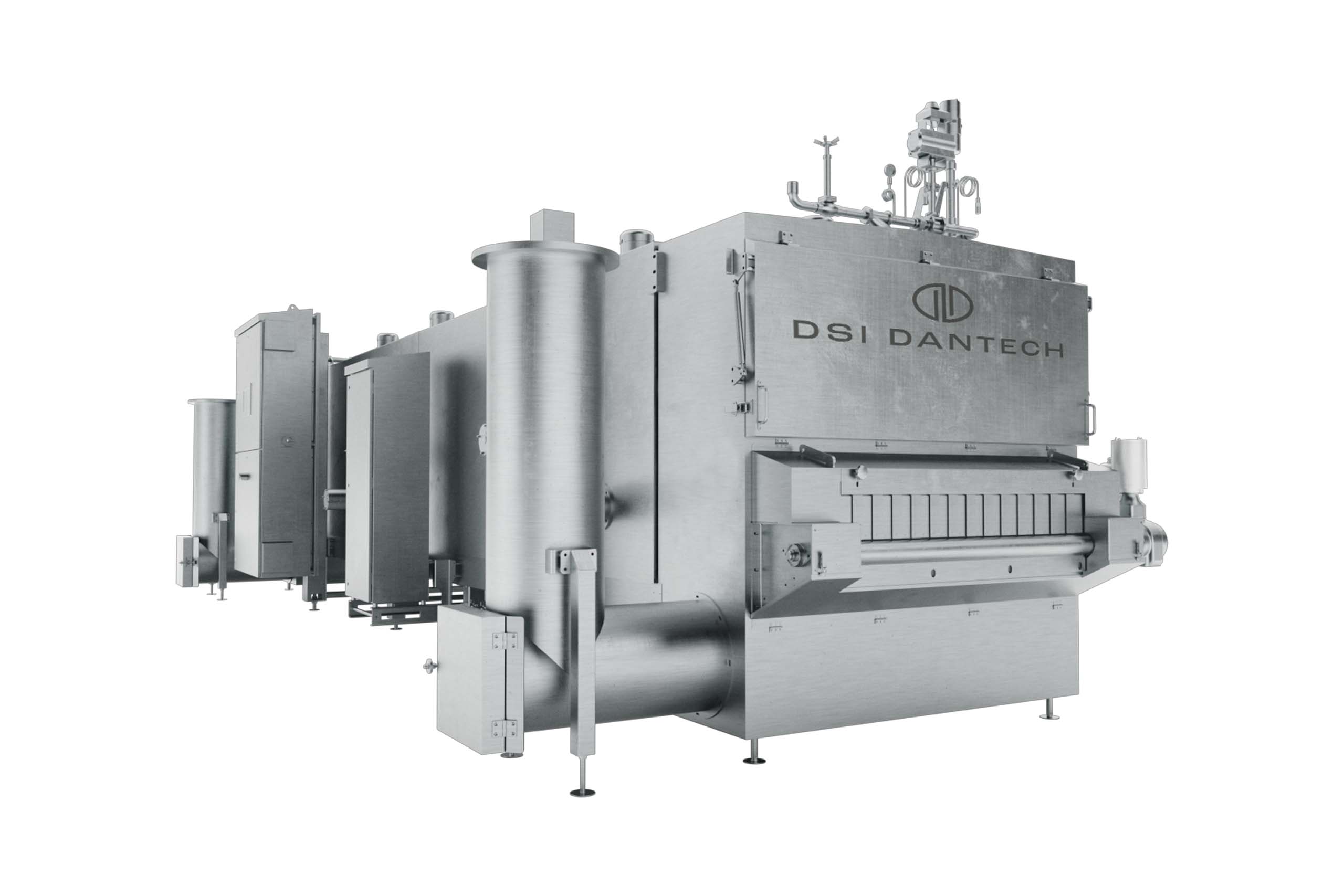

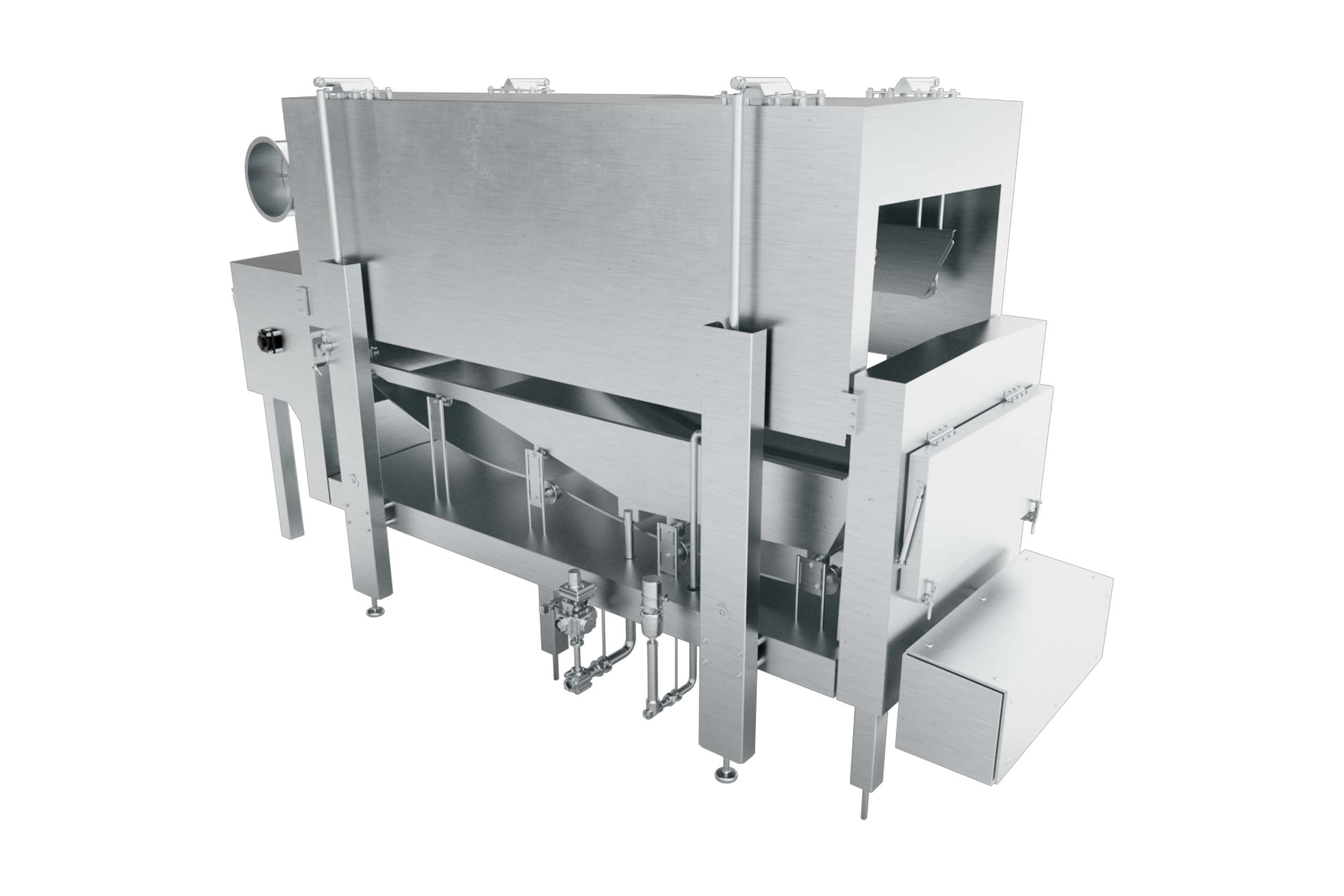

The cryogenic tunnel systems are designed to achieve fast freezing or chilling without causing thermal shock, yield loss, or dehydration to the product. The freezers are made of stainless steel to ensure a trouble-free operation and outstanding service life. Each of our IQF freezing tunnel systems can be standalone machines, or they can be joint for additional processing.