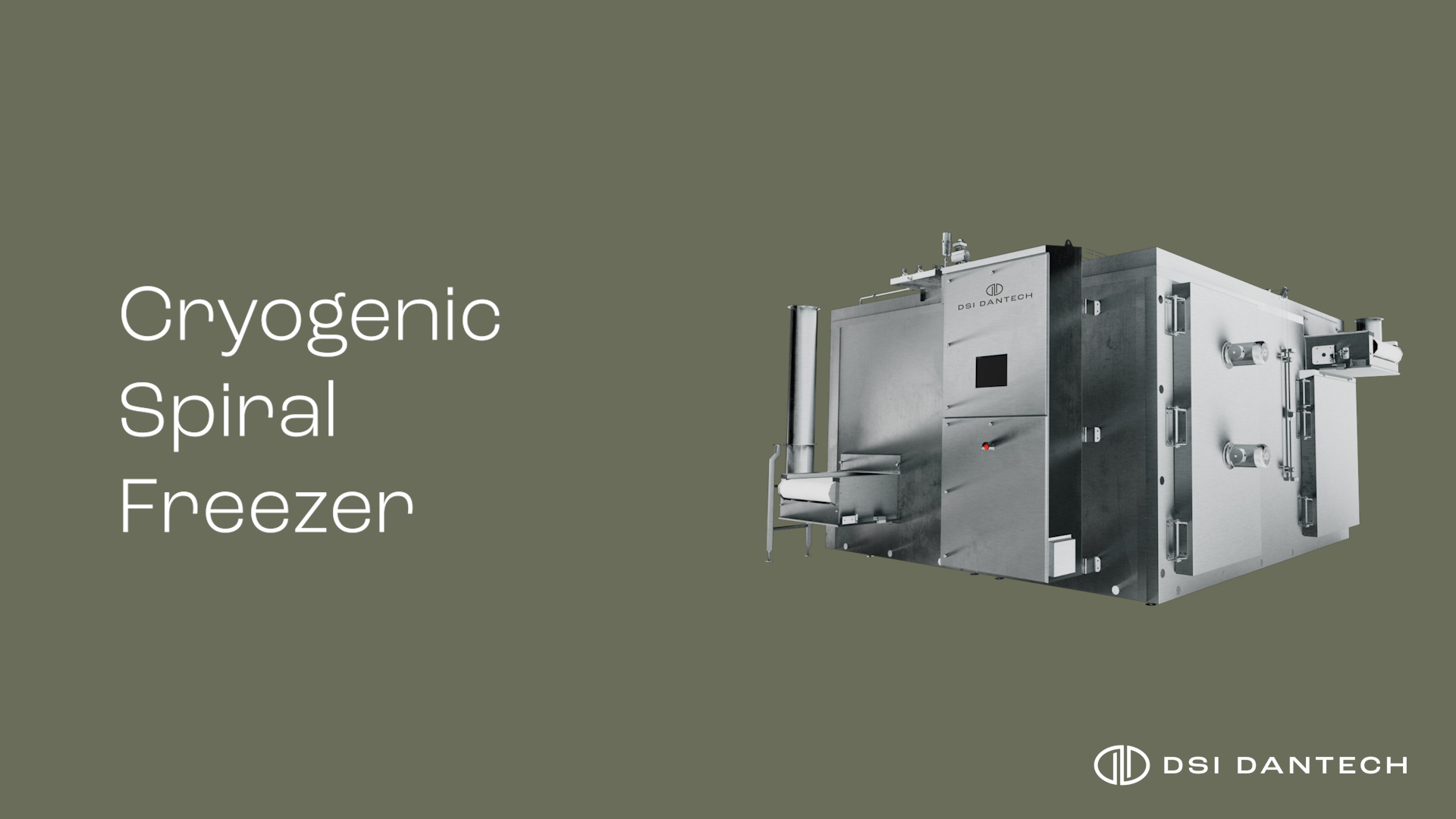

IQF spiral freezers

IQF cryogenic spiral solutions are ideal for large volume freezing and chilling of a very wide range of food.

The method is used in many industries such as meat & poultry, fish, baked goods, dairy products, and ready meals. It is also a good match for food with a long residence time or productions with minimal available floor space.

A cryogenic spiral freezer consists of a freezer-belt encircling a rotating drum. The food enters on a belt at the bottom of the drum, it then wraps in a helix to the top where it exits. Although the heat transfer rates of a cryogenic spiral freezer are slower than other cryogenic freezing and chilling equipment, it can contain as much as 450 feet of belt, allowing for very high production rates.

All our cryogenic spiral freezers can chill, crust, and fully freeze foods very quickly. They are designed for easy cleaning and maintenance, and they use liquid nitrogen or liquid carbon dioxide as the refrigerant. On top of that, you are likely to minimize the cost per kg treated product and achieve a much higher yield.