Customized automation solutions

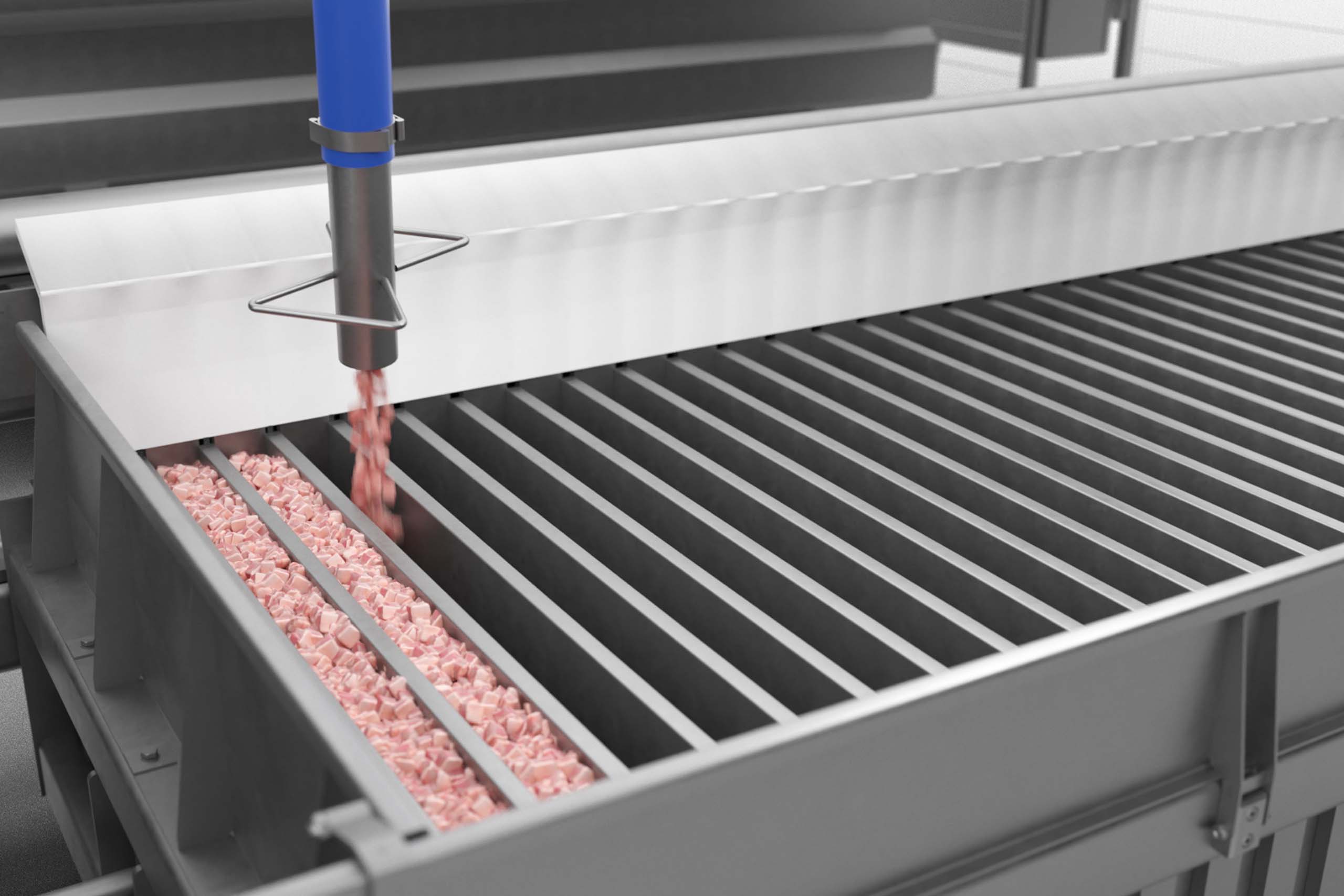

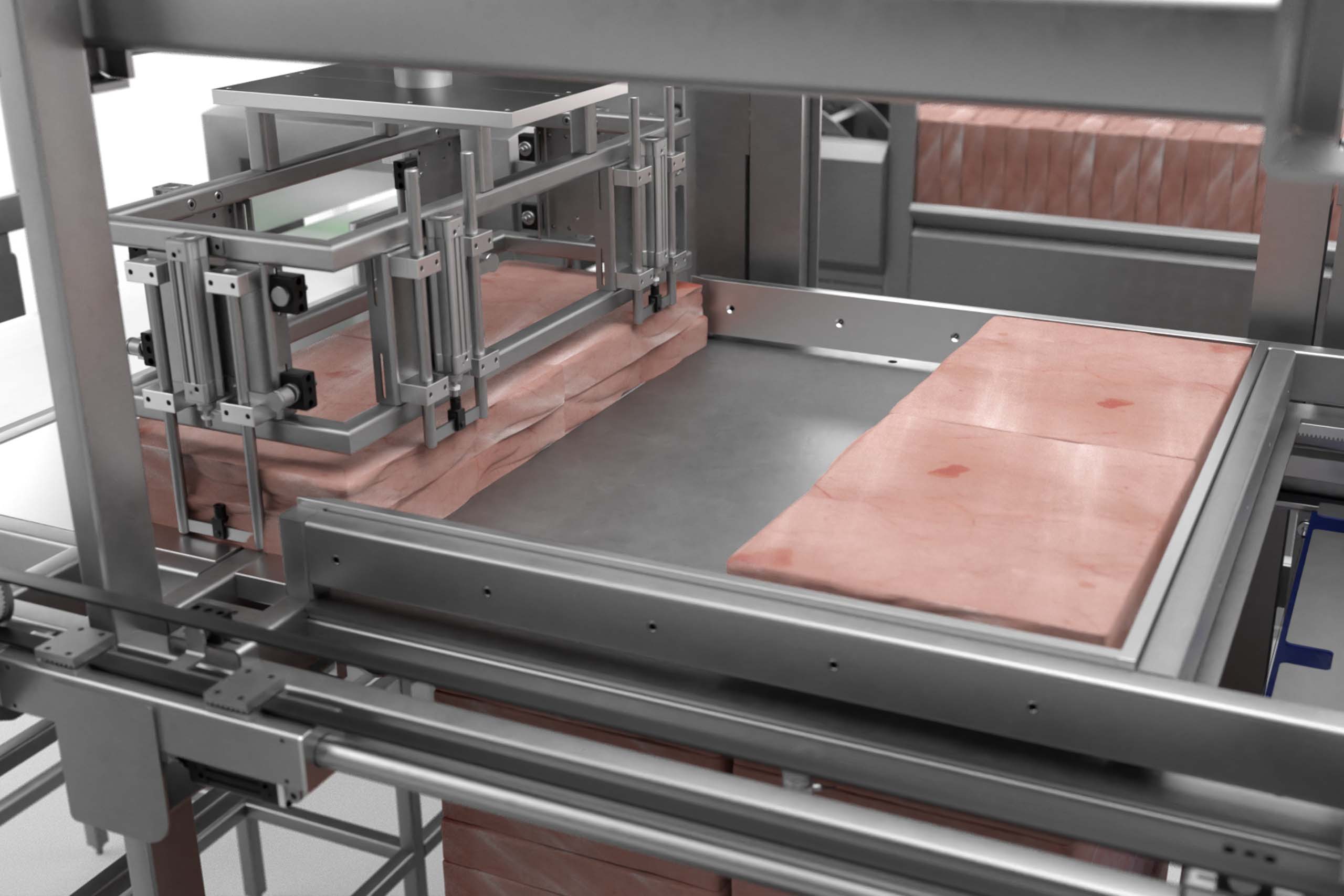

Maximize production efficiency and minimize production costs with automatic auxiliary equipment and handling solutions. Automating your production will also have a positive effect on safety, hygiene, and labor costs.

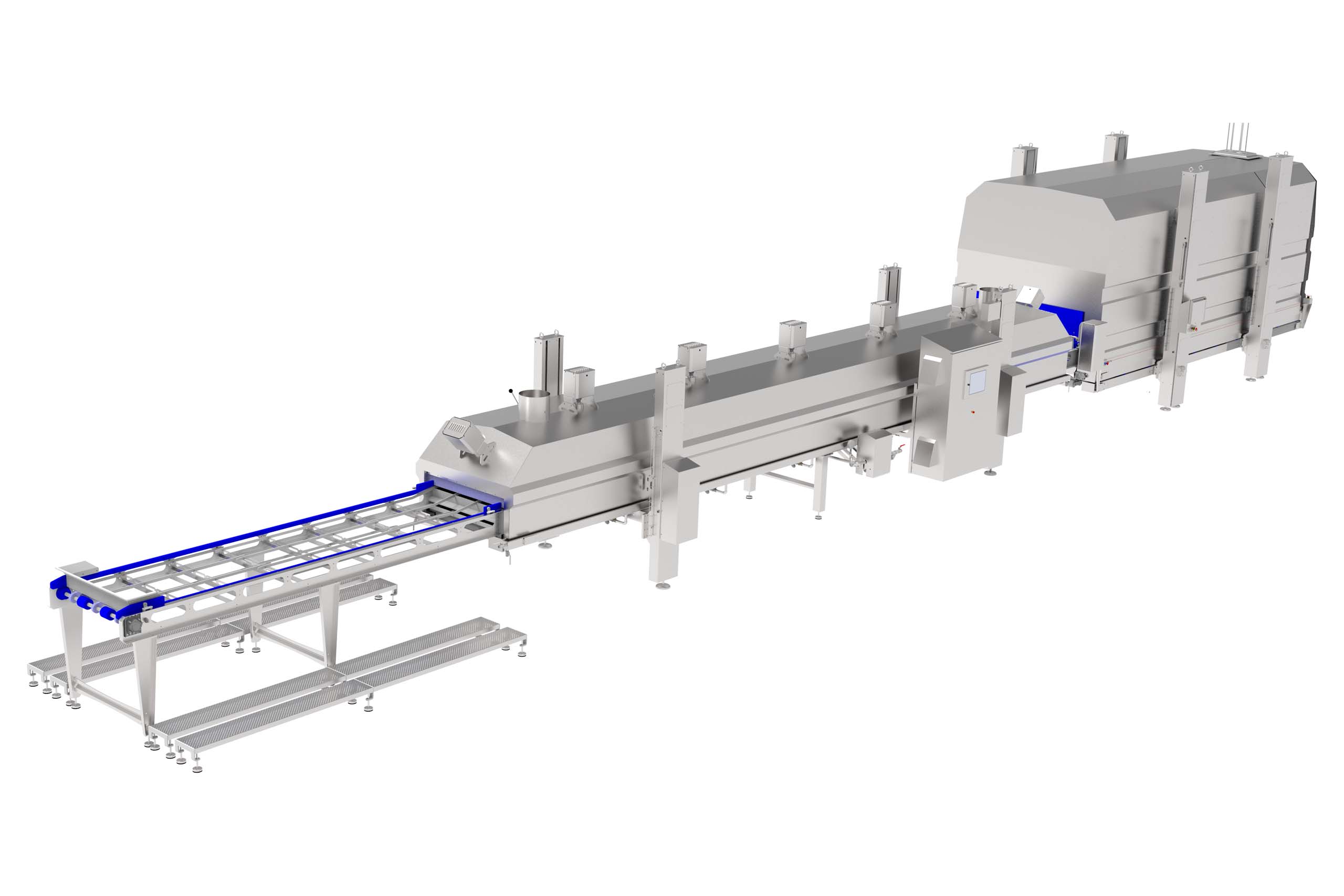

As the only all-in-one supplier of complete freezing, cooling, and heating solutions, we customize automation solutions for all processes from conveyor systems, crane rail constructions, pipe and pump loading systems, cranes, robots, stacking systems, palletizing conveyors, to stretch wrappers, etc.

You can choose manual, semi-, or fully automated equipment, or you can add modules to your existing facility to obtain an all-in-one solution that combines the thermal treatment you need with state-of-the-art handling equipment.